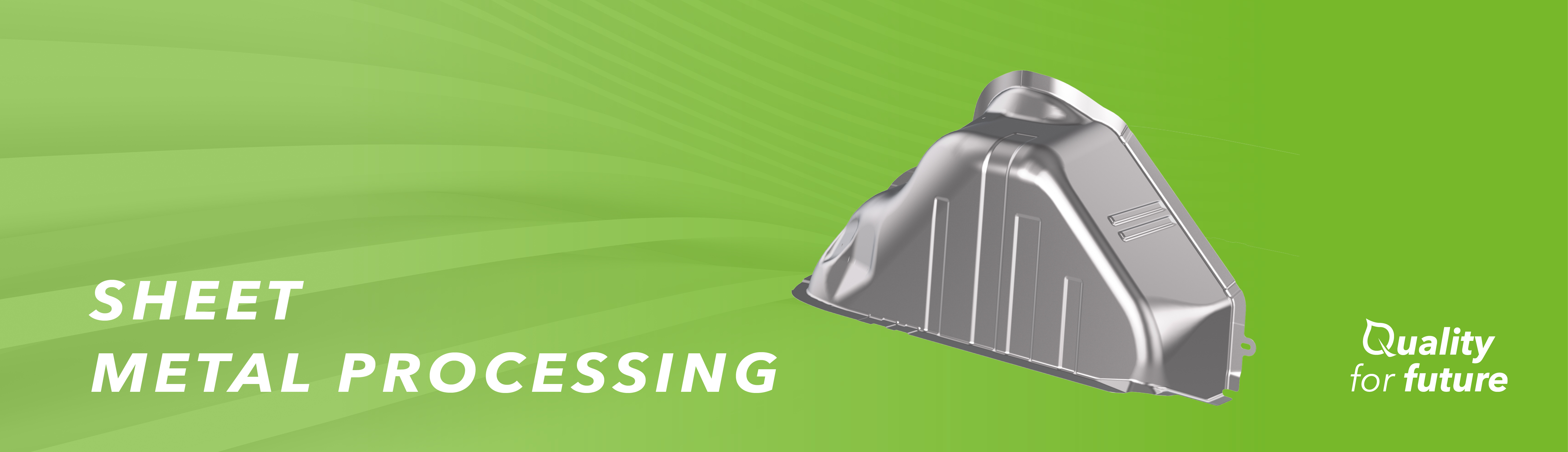

Sheet metal processing

An extensive machine park enables a wide range of manufacturing processes for sophisticated products.

Production is carried out on mechanical and hydraulic presses with press forces of up to 20,000 kN, some of which are also equipped with coil lines. Multi-acting presses with drawing and slide cushions enable the production of cold formed parts made of steel, aluminium and stainless steel.

The parts transport can be done for small and medium series up to 50,000 pcs. p.a. in manual replenishment as well as in an automated production in transfer.

The processed sheets can be treated in the downstream subassembly production by using wide strips of joining techniques and special productions, from individual parts to complex system assemblies.

Mainly in the welding and press-fit area, the different joining techniques are implemented manually but also automatically.

The supply of components or joining assemblies with appropriate surface treatment with the involvement of external service providers enables our customers to use a broad value chain in sheet processing.